20 kHz Ultrasonic Welders

|

Our 20 kHz ultrasonic welding equipment offers you maximum flexibility to take advantage of the benefits of the most commonly used ultrasonic frequency for plastics assembly. The 20 kHz frequency is the industry standard, suitable for a wide range of applications and thermoplastic components.

The X-Press is powered by a built-in microprocessor-controlled generator; Models 2050 and 2055 require a GX-Series Power Supply as shown below. |

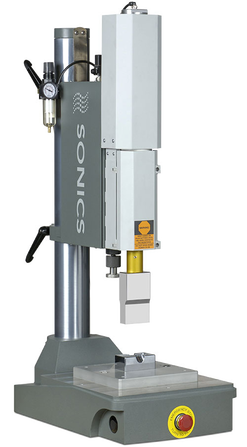

Model X-PressThe 20 kHz X-Press integrated welder is an all-in-one super-rigid ultrasonic press that combines power, versatility and microprocessor control in one convenient unit.

Features integral power supply

|

Model 2050The new GX-Series provides microprocessor control and consistent reliability for every application, and delivers more output power to the Model 2050 press, easily handling significantly larger part size and force requirements. Power supplies feature smart-logic, user-friendly navigation and are available in three different welding mode configurations for maximum versatility and flexibility.

Requires GX-Series power supply (See below)

|

Model 2055The new GX-Series provides microprocessor control and consistent reliability for every application, and delivers more output power to the Model 2055 press, easily handling significantly larger part size and force requirements. Power supplies feature smart-logic, user-friendly navigation and are available in three different weldingmode configurations for maximum versatility and flexibility.

Requires GX-Series power supply

|

GX-Series Power SuppliesFor Models 2050 and 2055

Microprocessor-controlled ultrasonic generators with horn/stack frequency display and digital amplitude control. Available in 1200, 1700, 2200 and 3500 watts.

|