Thickness Gauges

|

Ultrasonic Thickness Gauges are designed to improve safety and ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary inspection tool used to measure the remaining walls of components such as pipelines, pressure vessels, storage tanks, etc. Precision gauges use single-element transducers to provide the minimum range and highest degree of accuracy possible. Common applications include metals and a variety of non-metals (i.e. glass, ceramic, plastic, etc.). |

Digital SeriesMT200 Portable

MT170 Portable MT160 Portable MT150 Portable |

Through Paint Capability Multi-mode SeriesMT660 Multi-mode

MT600 Multi-mode MT280 Multi-mode MT190 Multi-mode MT180 Multi-mode |

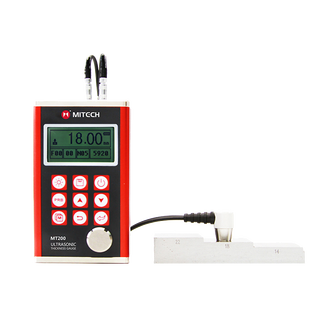

Model MT200 |

Model MT180 / MT190 |

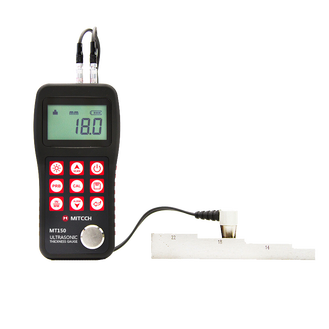

Model MT150 / MT160 |

|

Based on the same operating principles as SONAR, the MT200 Portable is capable of measuring the thickness of various materials with accuracy as high as 0.01 millimeters, or 0.001inches. It is suitable for a variety of metallic and non-metallic materials.

|

The MT180/MT190 is a multi-mode ultrasonic thickness gauge. Based on the same operating principles as SONAR, the instrument is capable of measuring the thickness of various materials with accuracy as high as 0.1/0.01 millimeters. The multi-mode feature of the gauge allows the user to toggle between pulse-echo mode (flaw and pit detection), and echo-echo mode (eliminate paint or coating thickness).

|

Based on the same operating principles as SONAR, the MT150/MT160 Portable is capable of measuring the thickness of various materials with accuracy as high as 0.1/0.01 millimeters respectively. It is suitable for a variety of metallic and non-metallic materials.

|