Seam Welders

|

Sonics’ seam welding systems can accommodate a wide range of copper and aluminum foil applications. A wide range of configurations are available for applications such as web roll, heat exchangers, continuous foil sealing and gantry mounting.

|

Metal Welding

|

|

Patented nodal mounting system.

Patented 90° self-orienting keyed horns and tips.

Model MSW20 |

Model MSWA20 Vertical Actuator |

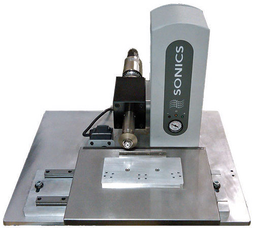

Model MSW20A20ST12 Actuator with Motorized Slide Table and Plate |

Model MSWA20RA Actuator with Rotary Anvil and Plate |

Rigid Dual Cross Roller Bearing Stack Housing

Steel Ultrasonic Rotary Horn

Weld Patterns Available in Various Widths and Knurl Patterns

Zero Contact and Frictionless Rotary Commutator

Single Piece, Dual Nodal Mount Horn and Booster Stack

Steel Ultrasonic Rotary Horn

Weld Patterns Available in Various Widths and Knurl Patterns

Zero Contact and Frictionless Rotary Commutator

Single Piece, Dual Nodal Mount Horn and Booster Stack

Application Examples

Welding the ends of foils to form a continuous web

Fabricating a continuous tubing from flat stock

Bonding copper and aluminum sheets to tubes to fabricate thermal solar systems

Bonding conductors to photovoltaic cells

SmartControl Power SuppliesUsing the full color touchscreen, the operator can intuitively enter weld parameters with job storage and recall capabilities. Available in 1500, 2500 and 4000 watts peak power.

|