Sonicators,

|

The state-of-the-art signal processor offers precision and high reactivity to the slightest trial conditions modifications. The patented NexTgen board is all the more reliable and robust. Moreover, the sonicator' ultrasonic generator maximum power has been designed to meet the sonicator and probe most important requirements.

|

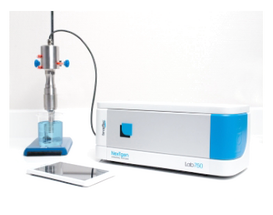

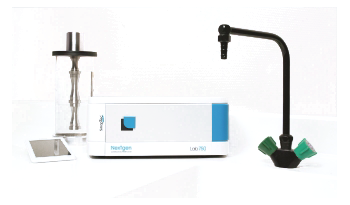

The worldwide patented NexTgen Ultrasonic power supply is one of the most advanced technology developed. It is available from 120W to 750W power supply for laboratory liquid processing. For industrial use, power can be increased up to 3kWpeak for large volume or circulating process. A very easy to used LabTablet is supplied with the LAB-generator to manage the power setting and time. All the user defined parameters are recorded in the NexTgen Ultrasonic processor and it is possible to keep in memory the setting configuration. Many parameters of the generators can be defined by computer thanks to an Ethernet connection with our “Advanced” and “LabPremium” computer softwares. These softwares also enable our support team to worldwide remote diagnosis and assistance.

|

Advanced control and data acquisition software

|

Our software tools enable parameters to be optimised and different control modes to be tested. This new intuitive concept makes the development and integration of ultrasound equipment considerably easier and allows our clients to control this important, industry specific stage.

Depending on the application, different control modes can be implemented and used by the patented NexTgen platform. These control modes are characterised, for example, by frequency management mode on the one hand, and the power management mode on the other. |

The benefits of this technology are:

|

for Axial ProbeUltrasonic sonicator with Axial probes are perfectly adapted for small volumes and high local intensities.

|

for Radial ProbeSonicator with Radial probes produce an exceptional power density and permits the evaluation of continuous process.

|

for Pipe ProcessorPipe processor is the best solution for lab trials before industrial scale-up. And the ultrasonic cup-horn probe is used to treat microtubes or samples.

|

Universal GeneratorsThe generators can be set to control piezoelectric transducers, which work within a frequency range from between a few kilohertz to 100 kHz and with a continuous power range from 1 W to 3 kWpeak.

They can be controlled either through the digital input and output or through Ethernet or RS485 communication. |