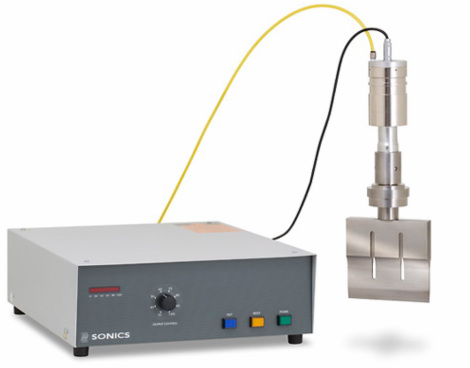

ULTRASONIC CUTTING systems

A worldwide leader in ultrasonic technology since 1969, Sonics offers a full line of cutting system components, kits and cutting horns, offering superior performance in terms of speed, safety, sanitation, reliability, and cost-effectiveness. When used for guillotine cutting or continuous slitting, our high frequency vibrating horns cut faster and cleaner than conventional motionless cutters.

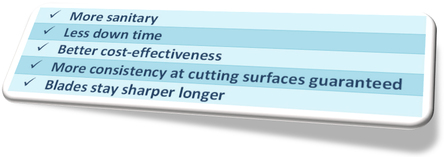

The ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product. Because the horn is vibrating at such a high frequency, it disrupts the air molecules around it causing a cocoon effect. This cocoon effect virtually eliminates product sticking and with reduced friction, the ultrasonic horn stays sharper longer than conventional cutters.

The ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product. Because the horn is vibrating at such a high frequency, it disrupts the air molecules around it causing a cocoon effect. This cocoon effect virtually eliminates product sticking and with reduced friction, the ultrasonic horn stays sharper longer than conventional cutters.

+ Stackable, ultrasonic power supplies and panel mountgenerator kits for NEMA enclosure, integration and sequencing

+ Rigid mount ultrasonic boosters for improved stack stability

+ Wash-down duty, air-cooled converters (stainless steel body also available)

+ Food industry approved titanium blade, slitting and knife horns

+ FEA analyzed horn designs for long life and amplitude accuracy

+ Rigid mount ultrasonic boosters for improved stack stability

+ Wash-down duty, air-cooled converters (stainless steel body also available)

+ Food industry approved titanium blade, slitting and knife horns

+ FEA analyzed horn designs for long life and amplitude accuracy