ULTRASONIC CUTTING hand-held

the all-new USW334K and ZO-41PLUS

Entirely fresh yet inherently familiar, greater cutting performance is the assurance.

|

Product Features

|

Application Examples

|

|

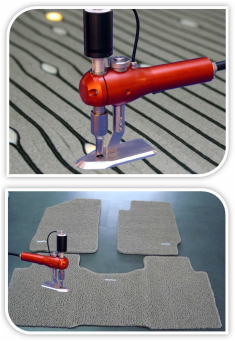

The introduction of the Petite series-based Model USW334 has made ultrasonic cutting an affordable solution to multiple applications with its compact design, especially targeted for small-medium enterprises (SMEs).

|

|

|

Product Features

|

Application Examples

|

|

The Petite series-based Model USW334ek has made ultrasonic engraving more do-it-yourself (DIY) than never before. At an affordable pricing, this small portable device is especially popular among Art Students and Institutions worldwide.

|

|

Product Features

Packed with enhanced features from its predecessor, the advanced-series ZO-41PLUS proves its powerful capabilities in most applications with a wide range of new blade designs available to choose from.

Quiet Operation

At 40,000 ultrasonic vibrations per second,the ultrasonic cutter cuts at a non-audible sound, reducing the friction during the cutting process.

|

Completely new.

|

Worldwide voltage accepted.We explored the whole of its predecessor, from the outside to deep within the system.

Designed with you in mind, the ZO-41PLUS is available for direct plug-in and use worldwide. |

Spend less. Cut more.

With a wide range of new blade designs to choose from,we give you our assurance of continued compatibility of most blades across our line of ultrasonic cutter models.

Because we do not want you spending unnecessary money on blades for each product model that you own. |

TAF Design.

The ZO-41PLUS is equipped with our new TAFTM circuit design to enhance the cutting consistency especially with hard-to-cut materials.

|

It's the simplicity you know and love.Equipped with a locked “ON” activation switch at a 10 minute operation, it is a simple addition we have included for you.

|

Cut like never before.

The new ZO-41PLUS allows you to switch between NORMAL and HIGH power more easily (5 minute operation).

|

We have built great features into this compact cutter model just so that you can enjoy all the power and toughness you require the next time you cut difficult materials. |

Application Examples

- Cutting of Soft Metals such as Aluminum copper

- Cutting of electrical components from the PCB for analysis

- Cutting of prepegs (fibres impregnated with resin) such as Carbon fibre, Glass fibre, Aramid fibre, etc.

- Cardboard, ABS, PET, PP, Acrylic

For a full list of suitable materials and specs, consult our sales representatives so that they can analyse your application and material for you.

|

Product Features

|

Application Examples

|

|

Packed with advanced features, the advanced-series USE337 proves its powerful capabilities in most applications.

|

|

|

Product Features

|

Application Examples

|